Logging-While-Drilling geoVISION* Tool

Description

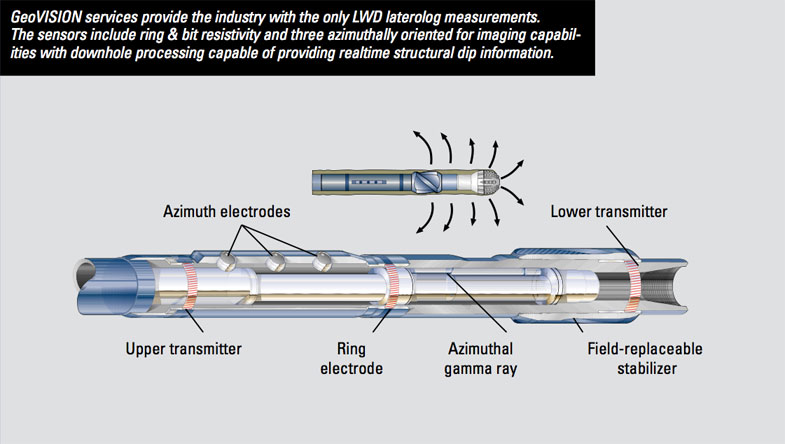

The Logging-While-Drilling-geoVISION (LWD-geoVISION) tool makes laterolog resistivity measurements. As a formation evaluation tool, its application is limited to conductive muds. It may be run in several configurations and provides up to five resistivity measurements. The geoVISION contains a scintillation gamma ray detector which supplies a total gamma ray measurement. An azimuthal positioning system allows both gamma ray and various resistivity measurements to be acquired around the borehole. Additional measurements are chassis temperature and radial and longitudinal shocks.

The Logging-While-Drilling-geoVISION (LWD-geoVISION) tool makes laterolog resistivity measurements. As a formation evaluation tool, its application is limited to conductive muds. It may be run in several configurations and provides up to five resistivity measurements. The geoVISION contains a scintillation gamma ray detector which supplies a total gamma ray measurement. An azimuthal positioning system allows both gamma ray and various resistivity measurements to be acquired around the borehole. Additional measurements are chassis temperature and radial and longitudinal shocks.

The geoVISION has a nominal 6.75-in (17 cm) diameter; it is meant to be run in 8.5-in (21.6 cm) holes. Designed to be a flexible component of the bottom hole assembly, the GVR6 may be connected directly behind the bit or further back in the bottom hole assembly.

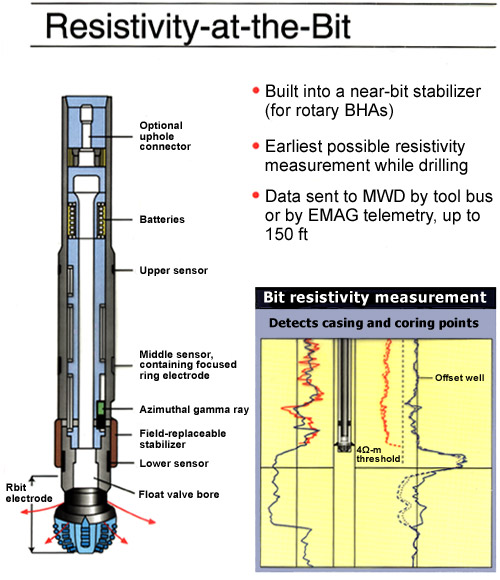

A 1.5-in (3.8 cm) tall cylindrical electrode, located 3 feet from the bottom of the tool, provides a focused lateral resistivity measurement (RING) with a 2-in (5 cm) vertical resolution, independent of the location of the RAB tool in the bottom hole assembly. In addition, the RAB sub has three longitudinally spaced button electrodes that provide staggered depths of investigation. As the tool rotates, azimuthal measurements are acquired from the button electrodes. When connected directly to the bit, the geoVISION uses the lower portion (8-in; 20.3 cm) of the tool and the bit as a measure electrode. In this configuration, it provides a bit resistivity measurement (RBIT) with a vertical resolution just a few inches longer than the length of the bit.

A 1.5-in (3.8 cm) tall cylindrical electrode, located 3 feet from the bottom of the tool, provides a focused lateral resistivity measurement (RING) with a 2-in (5 cm) vertical resolution, independent of the location of the RAB tool in the bottom hole assembly. In addition, the RAB sub has three longitudinally spaced button electrodes that provide staggered depths of investigation. As the tool rotates, azimuthal measurements are acquired from the button electrodes. When connected directly to the bit, the geoVISION uses the lower portion (8-in; 20.3 cm) of the tool and the bit as a measure electrode. In this configuration, it provides a bit resistivity measurement (RBIT) with a vertical resolution just a few inches longer than the length of the bit.

The geoVISION measurements have a high vertical and azimuthal resolution. To make the most of the vertical resolution, the optimal sampling density is greater than one sample every inch. At the maximum sampling interval of 10 sec, the optimal sampling density can be achieved for rates of penetration up to 29.5 ft/hr (9 m/hr). Achieving this vertical sampling is most important when imaging.

Applications

The geoVISION tool provides measurements with four depth of investigation to detect early invasion of borehole fluids into the formation, a sensor at the bit to ensure minimum invasion, azimuthal resistivity images of the borehole to detect resistivity heterogeneity, and a gamma-ray sensor for lithology characterization.

The geoVISION tool can also provide a close look at structural information within a fault zone or an active tectonic area with a resolution of 6-12 in (15-30 cm). The geoVISION measures oriented resistivity images of the borehole wall, similar to the FMS tool. Fracture orientations and distributions can be observed as resistivity contrasts in the image logs and are critical to recognize the extent of the deformation front along a tectonic front. Conversion of geoVISION images into relative porosity using Archie’s equation can be used in combination with density and porosity data to help define the azimuthal distribution of porosity and overpressurized zones which may contribute to fluid flow along planes of structural weakness.

Environmental Effects

The button measurements have a shallow depth of investigation by design, in order to be sensitive to shallow invasion. When the geoVISION tool is centralized in a 8.5-in (21.5 cm) hole, the buttons are 0.1875 in (0.47 cm) from the formation. Controlling this standoff insures correct measurements. Therefore, proper centralization is recommended.

The geoVISION processing automatically corrects the resistivity measurements for frequency effects and the effects of the borehole.

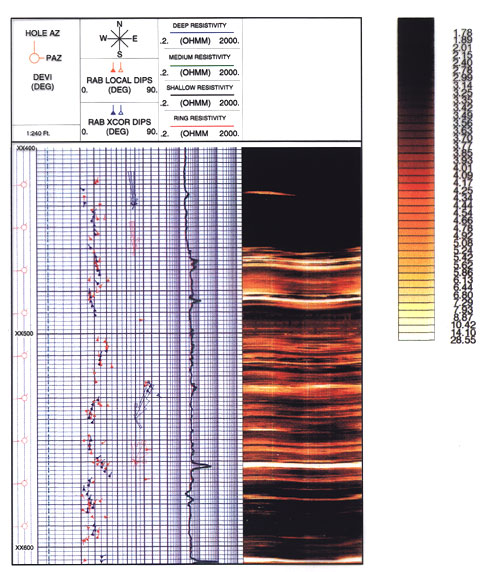

Log Presentation

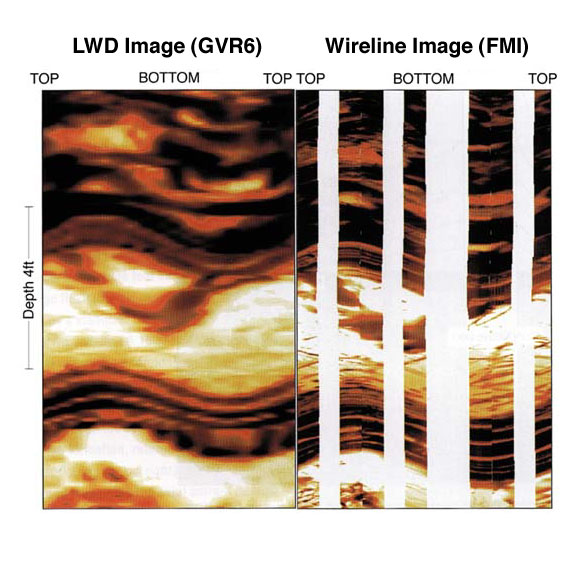

Comparison of geoVISION and Formation MicroImager (FMI)

Comparison of LWD-GVR6 tool and FMI tool electrical images in consolidated, highly fracture sediments. Both images of the interior of the borehole wall are oriented to the top of the deviated hole. Although the LWD tool has inferior bed resolution (by a factor of 30), it offers the advantage of data coverage around the entire circumference of the borehole and measurements within minutes after the hole has been drilled.

Tool Specifications

| Temperature rating | 300° F (149° C) |

| Pressure rating: | 18 kpsi (124 MPa) |

| Length: | 10 ft (3.3 m) |

| Weight: | 1,200 lbs (545 kg) |

| API nominal collar outside diameter: | 6.75 in (17.1 cm) |

| Maximum outside diameter: | 7.5 to 8.5 in (19.6 to 21.6 cm) |

| Minimum bit size: | 8.5 in (21.6 cm) |

| Maximum bit size: | 9.875 in (32.5 cm) |

| Flow range: | 0-800 gpm |

| Pressure drop coeffecient (C)*: | 135,000 |

| Maximum curvature – sliding: | 16 deg/100 ft (16 deg/31 m) |

| Maximum rotary torque: | 16,000 ft-lbf (4.877 m-lbf) |

| Minimum operating RPM: | 30 rpm |

| Uphole connection: | 5-1/2 FH box |

| Downhole connection: | 5-1/2 Reg box |

| (*) pressure drop = [mudweight in ppg] x [flow in gpm]²/C |

Measurement Specifications

| Gamma Ray | |

| Range: | 0-250 GAPI |

| Accuracy: | |

| Vertical resolution: | 1.5 in (3.81 cm) |

| Deep resistivity | |

| Range: | 0.2-1,000 ohm-m |

| Depth of investigation: | 5 in (12.7 cm) |

| Accuracy: | 5% (<200 ohm-m); 20% (>200 ohm-m) |

| Vertical resolution: | 2-3 in (5.08-7.62 cm) |

| Medium resistivity | |

| Range: | 0.2-1,000 ohm-m |

| Depth of investigation: | 3 in (7.62 cm) |

| Accuracy: | 5% (<200 ohm-m); 20% (>200 ohm-m) |

| Vertical resolution: | 2-3 in (5.08-7.62 cm) |

| Shallow resistivity | |

| Range: | 0.2-1,000 ohm-m |

| Depth of investigation: | 2-3 in (5.08-7.62 cm) |

| Accuracy: | 1 in (2.54 cm) |

| Vertical resolution: | 2-3 in (5.08-7.62 cm) |

| Ring resistivity | |

| Range: | 0.2-200,000 ohm-m |

| Depth of investigation: | 7 in (17.78 cm) |

| Accuracy: | 5% (0.2-200 ohm-m); 20% (>200 ohm-m) |

| Vertical resolution: | 2-3 in (5.08-7.62 cm) |

| Bit resistivity | |

| Range: | 0.2-200,000 ohm-m |

| Depth of investigation: | 12 in (30.48 cm) |

| Accuracy: | 5% (0.2-200 ohm-m); 20% (>200 ohm-m) |

| Vertical resolution: | 12-24 in (30.48-60.96 cm) |

Major Outputs

| GR: | Gamma ray average (API) |

| BDAV: | Deep resistivity average (ohm-m) |

| BMAV: | Medium resistivity average (ohm-m) |

| BSAV: | Shallow resistivity average (ohm-m) |

| RBIT: | Bit resistivity (ohm-m) |

| RING: | Ring resistivity (ohm-m) |

| B1TM: | Shallow resistivity time after bit (s) |

| B2TM | Medium resistivity time after bit (s) |

| B3TM: | Deep resistivity time after bit (s) |

| GRTK: | Gamma ray time after bit (s) |

| RBTM: | Bit resistivity time after bit (s) |

| RPM: | Rotational speed (rpm) |

| ROP5: | Rate of penetration per 5 ft (m/hr) |

| RTAB: | Ring time after bit (hr or min) |

| P1AZ: | P1 azimuth |

| HAZI: | Azimuth (deg) |

Static and dynamic images are output at 3 depths of investigation: medium, shallow, and deep.

* ®trademark of Schlumberger