Hostile Environment Litho-Density Sonde (HLDS*)

Description

The Hostile Environment Litho-Density Sonde (HLDS) uses a pad that is mechanically identical to that of the Hostile Environment Litho-Density tool (HLDT), but includes magnetic shielding and high-speed electronics. The entire pulse-height spectra from both detectors are recorded and processed into windows identical to those of the conventional Litho-Density measurement. Bulk density and photoelectric factor formation is conventionally derived; therefore, the tool response remains unchanged. The available spectral information is used for improved log and calibration quality control.

The Hostile Environment Litho-Density Sonde (HLDS) uses a pad that is mechanically identical to that of the Hostile Environment Litho-Density tool (HLDT), but includes magnetic shielding and high-speed electronics. The entire pulse-height spectra from both detectors are recorded and processed into windows identical to those of the conventional Litho-Density measurement. Bulk density and photoelectric factor formation is conventionally derived; therefore, the tool response remains unchanged. The available spectral information is used for improved log and calibration quality control.

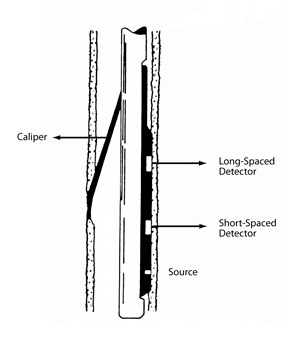

The HLDS consists of a 137Cs radioactive source and two detectors mounted on a shielded skid which is pressed against the formation by a hydraulically activated eccentering arm. The 662 keV gamma rays emitted by the source into the formation experience two types of interaction with the electrons in the formation — Compton scattering and photoelectric absorption.

Compton scattering is an elastic collision by which energy is transferred from the gamma ray to the electrons in the formation. This interaction forms the basis of the density measurement; in fact, because the number of scattered gamma rays which reach the detectors is directly related to the number of electrons in the formation, the tool responds to the electron density of the rocks, which is in turn related to the bulk density.

Photoelectric absorption occurs when the gamma rays reach a low energy (<150 keV) level after being repeatedly scattered by the electrons in the formation. The photoelectric effect index is determined by comparing the counts from the far detector in the high energy region, where only Compton scattering occurs, with those in the low energy region, where the count rates depend on both reactions. The far detector is used because it has a greater depth of investigation. The response of the short-spacing detector, which is mostly influenced by mudcake (not present in boreholes where a seawater-based drilling fluid is used) and borehole rugosity is used to correct the density measurement for these effects.

As with the case of the sonic tool, the depth of investigation of the lithodensity tool cannot be easily quantified; it is in the range of tens of centimeters, depending on the density of the rock. The vertical resolution is 16 in (38 cm).

Applications

Porosity. If grain density is known, porosity can be calculated from the density log. Alternatively, porosity and density logs can together be used to calculate grain density.

Seismic impedance. The product of velocity and density can be utilized as input to synthetic seismogram computations.

Lithology and rock chemistry. In combination with the neutron log, the density log allows for the definition of the lithology and of lithologic boundaries. Because each element is characterized by a different photoelectric factor, this can be used, alone or in combination with other logs, to determine the lithologic type. Both density and photoelectric effect index are input parameters to some of the geochemical processing algorithms used onshore.

Environmental Effects

A reliable density measurement requires good contact between pad and formation. Because a caliper measurement is made during the recording, it is possible to check the quality of the contact. In the lithodensity tool the presence of mudcake and hole irregularities are automatically accounted for using a “spine and ribs” chart based on a series of laboratory measurements. The “spine” is the locus of the two counting rates (short and long spacing) without mudcake and the “ribs” trace out the counting rates for the presence of mudcake at a fixed formation density. The short and long spacing readings are automatically plotted on this chart and corrected for their departure from true value. The DRH channel represents the amount of correction applied.

Log Presentation

The primary curves are: bulk density (RHOM, in g/cm³), photoelectric effect (PEFL, in barns/electron), density correction (DRH, in g/cm³), and caliper (LCAL, in inches). They are usually displayed along with the neutron curve APLC. Also, DPHI (density porosity) can be computed and displayed by assuming a constant grain density of the matrix. DRH is useful for quality control of the data; if the tool is operating correctly it should be less than 0.1 g/cm³.

Tool Specifications

| Temperature rating: | 500° F (260° C ) |

| Pressure rating: | 25 kpsi (17.2.3 MPa) |

| Diameter: | 3.5 in (8.9 cm) |

| Length: | 12.58 ft (3.83 m) |

| Weight: | 402 lbs (182 kg) |

Measurement Specifications

|

Logging speed:

|

Standard: 1800 ft/hr (549 m/hr) High speed: 3600 ft/hr (1097 m/hr) |

| Vertical resolution: | Density, porosity, and PEF 15: in (38.1 cm) |

| Accuracy: | Density: ± 0.01 g/cm³ PEF: ± 6% Caliper: 16 in. (40.64 cm) |

| Depth of investigation: | Density, porosity, and PEF: 6 in. |

Major Outputs

| RHOM: | Bulk density (g/cm³) |

| DRH: | Bulk density correction (g/cm³) |

| PEFL: | Long-spaced photoelectric effect (barns/e-) |

| NRHB: | Enhanced bulk density (g/cm³) |

| LCAL: | Caliper (in) |

| HROM: | High res. bulk density (g/cm³) |

| HBDC: | High res. bulk density correction (g/cm³) |

| HLEF: | High res. photoelectric effect (barns/e-) |

| HDEB: | High res. enhanced bulk density (g/cm³) |

Deployment Notes

The HLDS is typically run with the HNGS and APS tools. It can be combined with the DIT, DLL, and HRLA tools.

* ®trademark of Schlumberger