Ultrasonic Borehole Imager (UBI*)

Description

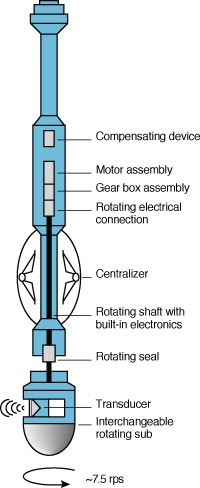

The Ultrasonic Borehole Imager features a high-resolution transducer that provides acoustic images of the borehole. Critical borehole stability and breakout information can be derived from the accurate borehole cross section measured by the tool. The high-resolution image from the transducer is also ideal for measuring casing internal geometry. The rotating transducer incorporated in the UBI sonde is both a transmitter and a receiver. The transducer subassembly is available in a variety of sizes for logging the complete range of normal openhole sizes. The subassembly is also selected to optimize the distance traveled by the ultrasonic sound pulse in the borehole fluid by reducing attenuation in heavy fluids and maintaining a good signal-to-noise ratio. For open hole applications, the UBI tool is logged with the transducer operating at either 250 or 500 kHz. The higher frequency has better image resolution, but the lower frequency provides a more robust measurement in highly dispersive muds.

The UBI tool measures amplitude and transit time. An innovative processing technique improves accuracy, avoids cycle skips and reduces echo losses, which makes the UBI transit-time measurement as reliable as that of the amplitude. The tool is relatively insensitive to eccentralization up to 1/4 in (0.6 cm)and yields images that are clean and easy to interpret, even in highly deviated wells. Processing software further enhances UBI images by correcting amplitude and transit-time information for the effects of logging speed variations and tool eccentering and by applying noise filtering. Transit times are converted to borehole radius information using the velocity of the ultrasonic signal in mud, measured by the tool on the way down. The images are oriented with inclinometry data from the combinable GPIT inclinometry tool and then enhanced by dynamic normalization and displayed as an image for visual interpretation. Amplitude and radius image data can be loaded on a geology workstation for analysis and interpretation. Major events can be automatically extracted from the radius data for wellbore stability evaluation.

Applications

High-resolution geological interpretation. The high resolution of open hole borehole wall images with 360° coverage makes the UBI tool suitable for dip and stratigraphic analysis, as well as fracture evaluation.

Borehole stability. Borehole stability problems can lead to stuck pipe, lost time, and even the loss of equipment or part of the well, resulting in added drilling costs. The UBI radius and the cross-section analysis accurately report the shape of the borehole, enabling a clear and detailed analysis of the problem.

Stress analysis. The UBI tool indications of stress anisotropy and orientation characterize borehole deformations such as breakouts for predicting perforation stability in unconsolidated formations. Shear sliding along a fracture or bedding plane can be detected with UBI radius measurements and cross-section plots, providing strong evidence of potential borehole and drilling problems.

Tool Specifications

| Temperature rating: | 350° F (177° C) |

| Pressure rating: | 20 kpsi (138 MPa) |

| Diameter: | 3.375 in (8.57 cm) |

| Length: | 21 in (6.4 cm) |

| Weight: | 377.6 lbs (171.4 kg) |

| Sampling interval: | 0.1 in (2.54 mm) |

| Logging speed: | 425 ft/hr (130 m/hr)- 2,125 ft/hr (648 m/hr), depending on desired resolution |

Measurement Specifications

| Vertical resolution: | 0.2 in (0.51 cm) at 500 kHz

0.4 in (1.02 cm) at 250 kHz |

| Depth of investigation: | Borehole wall |

| Accuracy: | Borehole radius: ± 0.12 in (± 3 mm) |

Major Outputs

Static and dynamic images are presented as an unwrapped borehole cylinder. Dark colors represent low amplitude and large radii, indicating borehole rugosity, enlargements and attenuative material. A dipping plane in the borehole appears as a sinusoid on the image: the amplitude of the sinusoid is proportional to the dip of the plane. The images are oriented with respect to the North; hence the strike of dipping features can be determined.

Deployment Notes

The UBI is typically deployed with the HNGS/EDTC/SGT and DSI tools.

* ®trademark of Schlumberger